Aviation Safety Invention Scores Top FAA Prize for Student Engineers

Roger Williams University engineering students earn national top honors for original wind shear detection device

BRISTOL, R.I. – With the invention of an original and economical wind shear detection device, four Roger Williams University engineering students earned top honors in the national 2014 Federal Aviation Administration Design Competition for Universities.

Samantha Gildersleeve ’14, Stephanie Norris ’14, Benny Tortorici ’14, and Andrew Wilson ’14 received first place in the runway safety category for their creation of the Protection Against Wind Shear (PAWS) system, a device that detects and transmits low-level wind shear at general aviation airports. Wind shear – a rapid change in wind speed or direction traveling at an angle – poses a serious hazard to departing and arriving planes, and can result in accidents and occasional fatalities.

An open-ended challenge, the competition required students to identify a significant aviation-related issue and engineer a solution to the problem, consulting airport operators and industry experts on their designs. The national FAA design challenge is open to all undergraduates and graduate students in colleges and universities across the United States.

The Roger Williams team researched challenges in runway safety and identified a gap in technology for detecting wind shear at general aviation airports, many of which are unable to afford the multimillion-dollar systems employed as a safety precaution at large commercial airports. Designing a system that senses vertical and horizontal low-level wind shear, their device records and analyzes wind speed and direction, wirelessly transmitting data to air traffic control while simultaneously providing a visual alert to pilots when wind shear is identified.

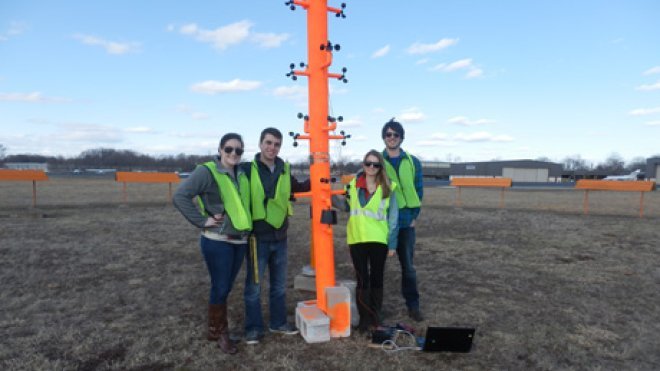

An original, and critical, part of their design was to engineer an affordable system – one that wouldn’t break the budgets of small-scale airports. At a cost of $10,000, their PAWS device self-generates electricity via two wind turbines and was constructed from market-available parts atop a simple, 50-foot steel pole, lending it the appearance of a day-glow orange telephone pole studded with whirling spoons.

Building a one-fifth-scale model, the team partnered with Tweed New Haven Regional Airport in New Haven, Conn., to successfully test the device numerous times.

The students worked under the guidance of Linda A. Riley, professor of engineering at RWU, over the 2013-14 academic year to complete this competition, which also served as their senior capstone project.

“The team conducted very thorough research and followed a classical design exploration path to focus in on what they wanted to solve,” said Riley, emphasizing the highly challenging nature of this open-ended competition that also required students to solicit advice and feedback from industry experts. “The students were faced with everything in this competition – coming up with their own problem, and design specifications and requirements. It attempts to parallel what the workplace looks like.”

As winners of the competition, the students will present their design at FAA headquarters in Washington, D.C., on July 29, as well as to top industry executives at a conference of the Airport Consultants Council in Arlington, Va., on July 30. Additionally, some of the most promising designs could receive FAA funding to further develop their inventions.